1 / 3

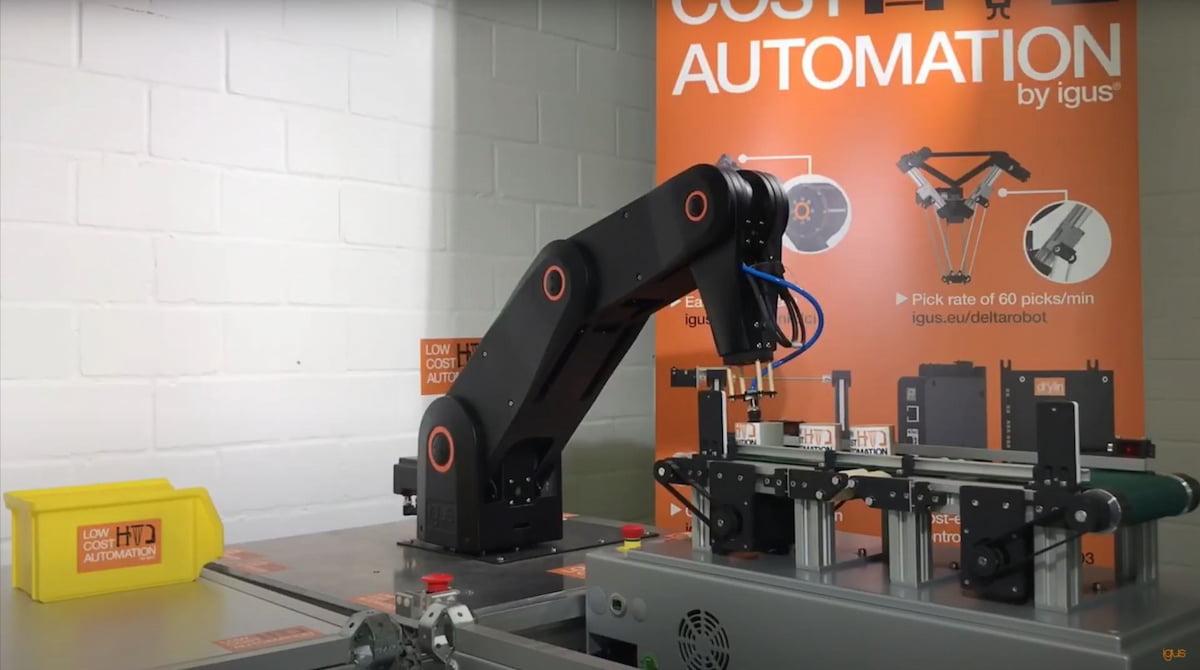

1 / 3Automated pick and place from conveyor belt

Test before Invest

Hardware Price:

DOF

5

Max. payload

3

kg

Repeatability

1

mm

Flexible Automation with Robolink and igus Robot Control

igus robotic kinematics provide maximum flexibility for setting up automation solutions, enabling fast and reliable pick-and-place tasks. In this example, a robolink robotic arm integrated with igus Robot Control (iRC) demonstrates how a conveyor belt can be seamlessly incorporated to automate pick-and-place operations. The iRC provides simple, intuitive controls, eliminating the need for advanced programming knowledge. Together with trusted partners, igus offers comprehensive support to help customers implement tailored automation applications efficiently and affordably.

What is the Application?

The system automates material handling tasks, such as pick-and-place on conveyor belts, making it ideal for industries like logistics, packaging, and manufacturing.

What are the Advantages of the Solution?

User-Friendly Setup: No programming knowledge is required for operation.

High Flexibility: Easily integrates with conveyor systems and other components.

Reliable Performance: Ensures fast and precise handling of products.

What are the Advantages of the Robot?

The robolink robotic arm offers:

Versatile Movability: Adapts to a range of pick-and-place applications.

Ease of Integration: Works seamlessly with igus Robot Control and partner solutions.

Scalable Design: Flexible kinematics support evolving operational needs.

Streamlining Pick-and-Place with igus Robolink

With igus robotic kinematics and iRC, businesses can achieve highly flexible and cost-effective automation solutions. Simplified controls, seamless integration, and reliable performance empower industries to automate workflows efficiently, ensuring smoother operations and increased productivity.

3 Components