1 / 4

1 / 4Vision based mushroom handling application

Test before Invest

Hardware Price:

DOF

3

Repeatability

0.5

mm

Max. velocity

1

meter per second

Pick-and-Place Automation for the Food Industry: Efficient Mushroom Handling

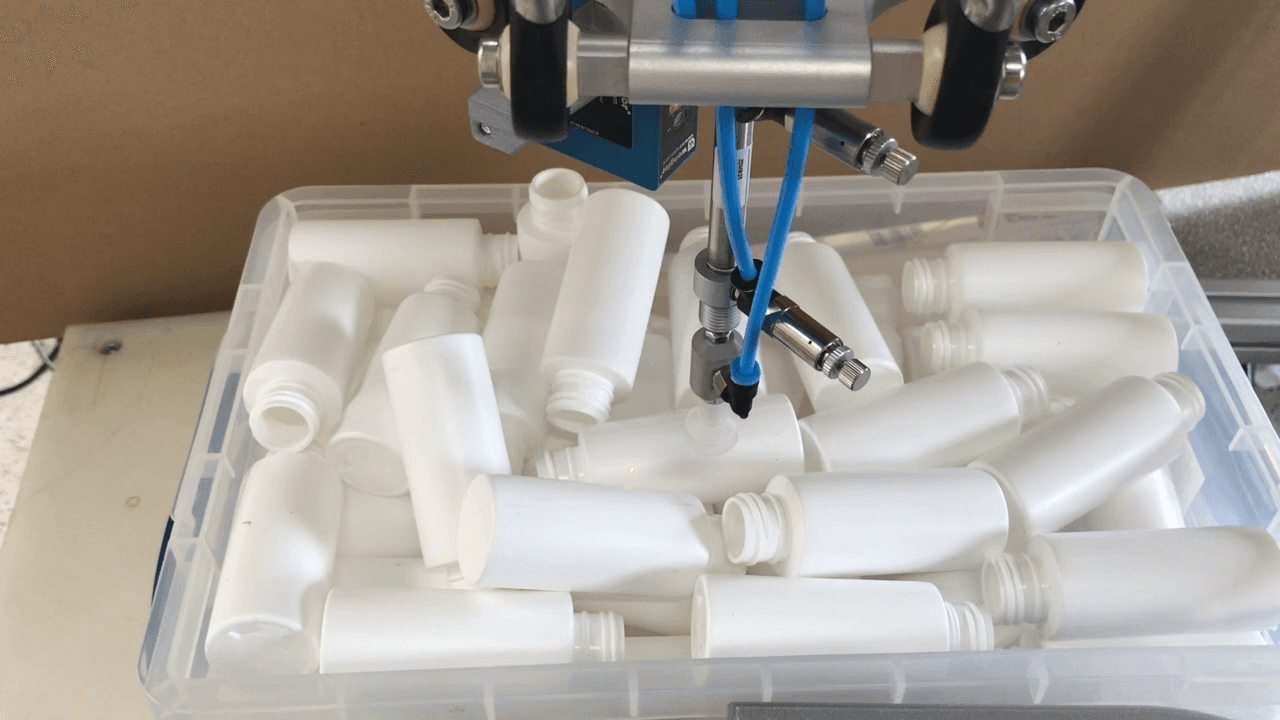

As part of a customer test in the igus Customer Testing Area in Cologne, a solution was developed to evaluate the automation of mushroom handling in the food industry. The test setup used an igus Delta Robot and an ifm 2D camera to automate the pick-and-place process of mushrooms from a conveyor belt. This system ensures high-speed, accurate operations, meeting the stringent hygiene and productivity demands of the food sector.

What is the Application?

The system automates mushroom picking from conveyor belts, using the 2D camera to detect object positions and the Delta Robot for precise gripping and placement.

What are the Advantages of the Solution?

High Speed: Achieves up to 100 picks per minute, optimizing workflow.

Precision: Accurate object detection and handling reduce waste.

Hygienic Design: Complies with food industry standards, supporting clean operations.

What are the Advantages of the Robot?

The igus Delta Robot delivers exceptional performance for pick-and-place tasks:

Flexible Kinematics: Supports 2- or 3-axis operations to fit various workspace sizes.

Ease of Use: Plug-and-play controls with free software simplify integration.

Reliability: Ensures consistent output, even in demanding workflows.

Revolutionizing Food Industry Automation with igus Technology

The combination of the igus Delta Robot and ifm 2D camera showcases how automation can optimize food handling processes. By increasing speed, precision, and reliability, this system provides a scalable and hygienic solution for pick-and-place tasks, enabling food businesses to meet productivity goals while reducing errors and manual intervention.

4 Components